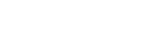

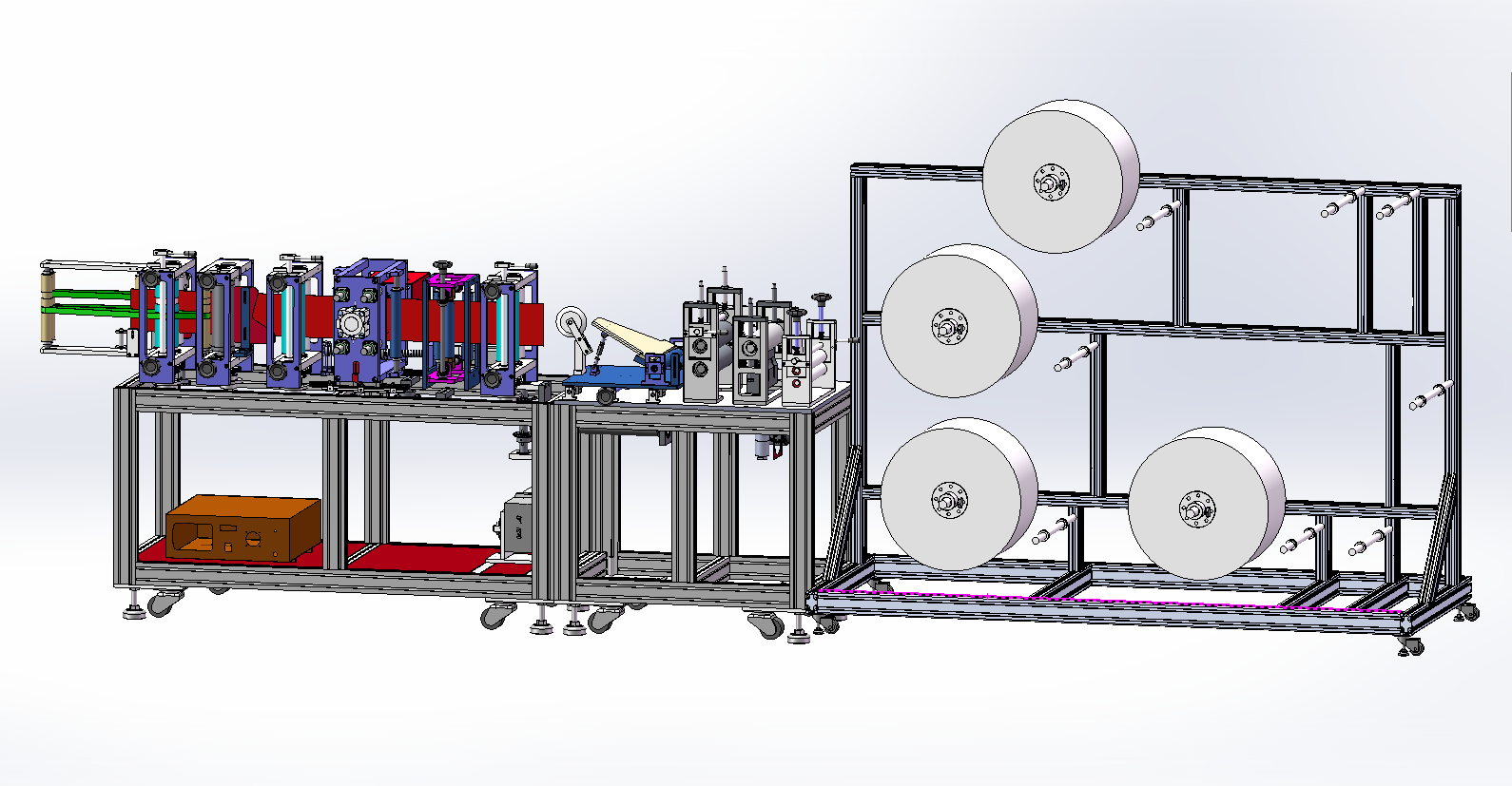

Illustration description

A: material rack

B: material roll

C: feeding station

D: welding position

E: discharging station

The basic parameters

|

Electric voltage

|

AC220V

|

|

Work rate

|

<750W

|

|

Maximum overall dimensions

|

1930*5050*900mm

|

|

Speed

|

3600-4000 PCs/h

|

Performance characteristics

Semi-automatic N95 mask integrated machine is a semi-automatic equipment independently developed and produced by Rosetta Stone Biotechnology Co., Ltd., which is fully automated and automatically fed from raw materials.

Without damaging the material, the filter performance is achieved, and the punching periphery is evenly pressed firmly, thus realizing the automatic production of the finished product of the mask, realizing the automatic operation of the whole machine, and having higher efficiency than the traditional manufacturing.

Machine characteristics

1. Integrated design, raw materials enter the finished products for output, fully automatic operation.

2. Automatic setting without damaging the material.

3. Several processes are integrated, with reasonable design and high efficiency.

4. The mask sheet is output by conveyor belt, with adjustable speed, neat sheet output, stable product quality, convenient operation and high production efficiency.

5. All-aluminum profile machine is neat and beautiful without welding. Man-machine interface touch screen control, built-in time, total output, equivalent, knob key to adjust the speed of film.

6. The motor is imported from Taiwan, with magnetic wheel deceleration belt braking function, and the noise is extremely low.

7. The mask is formed by ultrasonic welding with superior performance and high speed.

Remarks

1. If the customer has special requirements on voltage and frequency, the equipment in the project plan shall be re-quoted according to the voltage and frequency requirements.

2. The project plan refers to the standard equipment configuration provided according to the customer's project process. If there is any individual adjustment, or the customer needs to communicate and explain.

Contact Us

Contact:Ms.Jin Yuan or Ms.Mary Zhang

Email:sales@biotechrs.com or maryrongzhang@gmail.com